The steps and methods of valve machine fault handling are nothing more than

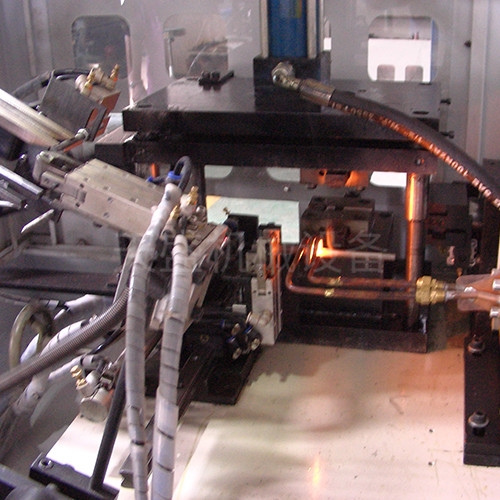

With the rapid development of China's mechanical processing, there are more and more domestic CNC valve machines. Due to the advanced nature of the CNC valve machine and the instability of the fault, and most of the faults appear in the form of comprehensive faults, the maintenance of the CNC valve machine is much more difficult, but the steps and methods of fault handling are nothing more than the following. What time is it.

1. Full investigation of the fault site

When a fault occurs, it is necessary to fully understand the circumstances under which the valve machine fault occurs. What happens when there is a phenomenon, what kind of measures the operator takes after the occurrence, such as the fault scene is still in place, it is necessary to carry out the contents of the CNC. Carefully observe the contents of the block being executed and the contents of the alarm displayed by self-diagnosis, and observe the status of the warning lights on each board. Then press the system reset button to see if the fault disappears. If the fault alarm disappears, such alarms are mostly software faults.

2. List all the factors that may cause the failure

The reasons for the same type of failure in CNC valve machines may be various, including mechanical, electrical, and control systems. Therefore, all relevant factors should be listed in the failure analysis. For example, the X-axis of the valve machine will shake when moving. The factors that may cause this phenomenon may be: a. The connection of the X-axis encoder may be poorly contacted; b. The island rail of the X-axis is too tight and the damping is too large. The X-axis motor load is too large; c, X-axis servo motor and screw coupling are loose or gap; d, X-axis motor servo drive has problems; e, X-axis servo motor is faulty and so on.

3. Method for determining the cause of the failure

There are many kinds of numerical control systems for numerical control valve machine tools, but no matter what kind of numerical control system, the following methods can be used to comprehensively judge the faults.

(1) Intuitive method: It is to use the human senses to pay attention to the phenomenon when a fault occurs and to determine the possible part of the fault. Where there is any abnormal noise, sparks, where there is a burnt spot, where there is a fever abnormality, and then further observe the surface condition of each board that may malfunction, such as whether there is any on the board Burning, blackening or electronic components have a crack, to further narrow the inspection scope. This is a basic and simple method, but requires the valve machine maintenance personnel to have certain maintenance experience.

(2) Using the hardware alarm function of the numerical control system: the alarm indicator can judge the fault. There are a lot of alarm indicators on the hardware circuit board of the CNC system, which can roughly determine the location of the fault.

(3) Make full use of the software alarm function of the CNC system: The CNC system has self-diagnosis function. The system can be quickly diagnosed with a self-diagnostic program during system operation. Once the fault is detected, the fault is immediately displayed on the form screen in the alarm mode or each alarm light is illuminated. The fault of the valve machine can be found according to the alarm content prompt during maintenance.

(4) Diagnostic function using status display: The numerical control system can not only display the fault diagnosis information, but also provide various statuses of valve machine diagnosis in the form of diagnostic address and diagnostic data, for example, between the system and the valve machine. The input/output signal status of the interface, or the signal status of the input/output between the PC and the CNC device, and the interface between the PC and the valve machine, can be used to check whether the CNC system inputs the signal by using the status display of the display screen. Whether the valve information of the valve machine or the valve machine has been input to the CNC system. In short, the fault can be distinguished whether it is on the side of the valve machine or on the side of the CNC system, so that the inspection range of the CNC valve machine fault can be reduced.

(5) When the fault occurs, the CNC system parameters should be checked in time: the system parameter changes will directly affect the performance of the valve machine, and even the valve machine will malfunction, and the whole valve machine will not work. The external interference may cause changes in the individual parameters in the memory, so when the valve machine has some inexplicable faults, the parameters of the numerical control system can be checked.

(6) Spare parts replacement method: When the valve machine fault is analyzed and it is found that the circuit board may be faulty, the spare board can be replaced, and the faulty circuit board can be quickly determined. However, the following two points should be noted when using this method: 1. Pay attention to the position of each adjustable switch on the circuit board. When changing the board, pay attention to make the setting state of the two boards being exchanged exactly the same, otherwise Make the system unstable or not good, and even have an alarm. 2 After replacing some boards (such as CCU board), you need to reset or input the parameters and programs of the valve machine.

(7) Use the detection terminal on the circuit board: There is a detection terminal on the circuit board for measuring the voltage and waveform of the circuit, so as to determine whether the circuit works normally during debugging and maintenance. However, when testing this part of the circuit, you should be familiar with the circuit principle and the logical relationship of the circuit. In the case of unfamiliar logical relationships, two identical board comparisons can be used to detect the board's failure.

In short, when a numerical control valve machine fails, the maintenance personnel can correctly determine the cause of the failure and the location of the fault by following the above-mentioned detection steps and methods.

The address of this article:http://laquintademahler.com/en/news/409.html

Key word:氣門磨床,氣門設(shè)備,氣門車床

Recently browse:

Related products:

Related news:

- Learn about the independent entry and exit of the valve lathe system

- Safety precautions for using valve lathes

- So how should the principle and function of the valve device be understood?

- Talk about the special equipment for the valve starting and starting the valve

- Tell me more about how the valve lathe controls the operation.

- How to make the industry of valve lathe processing rise

- What adjusts the clearance of the valve lathe?

- Tiansheng Xiaobian explains to you the classification of engine variable valve equipment intake

- Main features of welding of rod end drilling machine for valve equipment

- What are the advantages of an automatic valve lathe as a guide feed thrust?